An optical splitter dissects a singular fiber optic signal into multiple pathways based on predetermined ratios, acting as a connector for one input and various output ends. This device is particularly apt for passive optical networks (such as EPON, GPON, BPON) and stands as one of the most prevalent passive optical components in FTTx solutions.

PLC (Planar Lightwave Circuit) Optical Splitters

The PLC optical splitter, rooted in quartz substrate technology, epitomizes an integrated waveguide optical power distributor. It is crafted utilizing semiconductor processes (such as photolithography, etching, and developing techniques). The PLC splitter adeptly divides optical signals from one fiber into several fibers while ensuring an equitable distribution of optical energy.

Classification of PLC Splitters

Mini PLC Optical Splitter

This can also be referred to as a mini-tube PLC splitter. It bears a striking resemblance to the bare fiber type PLC splitter, yet it boasts a more compact stainless steel tube enclosure, offering enhanced protection for the fibers. At the fiber ends, connectors are present (common types include SC, LC, and FC connectors), thus obviating the need for fiber splicing during installation. The mini PLC splitter finds extensive application in various settings such as fiber distribution boxes, rack-mounted optical distribution frames, or cabinets, facilitating diverse connectivity scenarios.

Cassette PLC Optical Splitter

Resembling the LGX PLC splitter in appearance, the cassette-type PLC splitter is a more compact iteration of the same, designed with spatial efficiency in mind. It is typically installed in wall-mounted FTTH fiber distribution boxes for the distribution of optical signals. The utilization of cassette-type PLC splitters offers time and space efficiency while ensuring reliable protection for the optical splitters. This design is particularly well-suited for FTTx projects, especially at distribution points near end-users in FTTx networks.

Box-type PLC Optical Splitter

Alternatively known as the ABS box-type PLC splitter, this variant features both the input and output fibers aligned on the same side of the ABS enclosure. This design accommodates various installation requirements and offers more flexible cabling solutions. Additionally, it can be installed in a variety of distribution cabinets or racks, and is compatible with integrated trays and rack assemblies.

Rack-Mount PLC Optical Splitter

Also referred to as the rack-mount optical splitter, it is designed for integration into any standard 19-inch rack, catering to the high-density cabling needs of data centers or server rooms. The rack-mount enclosure facilitates easy installation in fiber optic projects and provides robust protection for the PLC splitter components. It is available in 1U or 2U rack-mount configurations, along with a variety of adapters, such as SC, LC, and FC connectors.

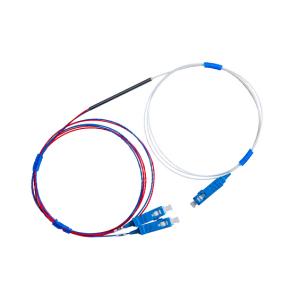

FBT Optical Splitter

The FBT (Fused Biconical Taper) optical splitter, akin in appearance to the bare fiber type PLC splitter and the mini-tube PLC splitter, operates on a different principle. In this process, two or more fibers are fused and tapered together on a tapering machine, with real-time monitoring of the splitting ratio. The process concludes once the desired splitting ratio is achieved. One end retains a single fiber as the input, while the other end serves as the multi-path output. Given the fragility of the fused fibers, they are protected by a glass tube made from epoxy resin and silica powder, further encased in a stainless steel tube and sealed with silicone. FBT splitters typically come in configurations like 1×2 or 1×4. For demands exceeding 1×4, multiple 1×2 units are connected together and then collectively encased in the splitter box.